Fineblanking for global markets

Finest Blanking is our attitude. It describes not only our processes, but also the way we work. At ELAY, every product and manufacturing method is meticulously managed, combining precision, safety and quality. We are committed to innovation and continuous improvement, using the most advanced technology to offer agile and efficient solutions to our customers.

We anticipate industry challenges with creativity and expertise, developing cutting-edge processes that optimise results and raise industry standards. This is the commitment and guarantee that ELAY offers: excellence with a vision for the future.

Production plants

Sales offices

Employees

Million of € in sales

DOIKA Process

Precision, Control, Automation and Integration

DOIKA represents our essence of Precision, Control, Automation and Integration in the production of highly complex metal components. This allows us to guarantee our customers reliable parts of exceptional quality, perfectly integrated into their production processes.

More than a method, DOIKA Process is a standard of excellence: on-time deliveries, optimised processes with no margin for error and an adaptability that meets the highest demands.

View moreApplications

Automotive industry

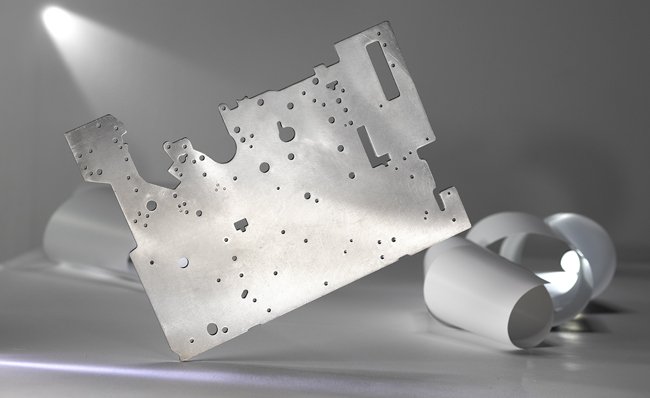

Value-added fineblanking

At ELAY, we manufacture precision metal components for various uses including seats, chassis, locking and transmission systems. We have one of the widest ranges in the sector, both in terms of the number of references and in dimensions, thicknesses, materials and finishings.

We are a globally operating automotive parts supplier. Many of the leading brands in the sector incorporate parts produced in our plants.

View more

Other industries

Opening up new horizons

Our innovative spirit has led us to apply fineblanking technology in other sectors, where its added value was still unknown.

We have therefore diversified our activity by collaborating with industries seeking demanding technical solutions, adapting our processes to new applications with the same reliability as always.

View moreTecnologies

Innovation beyond fineblanking

As a leader in fineblanking, plastic overmoulding and advanced manufacturing processes, ELAY transforms complexity into precision. Our process engineering not only designs solutions, but integrates them with absolute control, ensuring quality, efficiency and reliability in every part produced.

Our development capacity allows us to manufacture complex parts with high technical difficulty, combining prototyping, simulation and innovative processes to adapt to the most demanding challenges of the industry.

View more

Fineblanking

We apply fineblanking technology to manufacture complex parts with very tight tolerances.

Plastic overmoulding

We use the plastic overmoulding technique, which allows complex parts with very narrow walls to be overmoulded by applying pressure.

Precision finishings

We have a range of precision finishing technologies to suit the requirements of each part.

Complementary operations

We offer integrated complementary processes or through our network of international partners.

Service

We create value beyond the product

At ELAY, we accompany the customer from the initial phases of the project to the final delivery. We collaborate in the development of solutions that are optimised in terms of functionality, cost and feasibility, and we have a flexible structure that guarantees reliable deliveries, in quantity and on time, anywhere in the world.

View more

Product co-design

At ELAY, we understand that a well-designed part starts long before it is manufactured. For this reason, we offer a co-design service focused on accompanying the customer from the initial stages of development, providing our specific know-how in fineblanking and die design.

Global logistics

At ELAY we offer logistics solutions capable of responding to our customers wherever they are.

We have the resources, network and experience to ensure reliable and efficient international deliveries.

Regardless of where the need arises, we are ready to support each project no matter where it is located.

View more

News

Last news

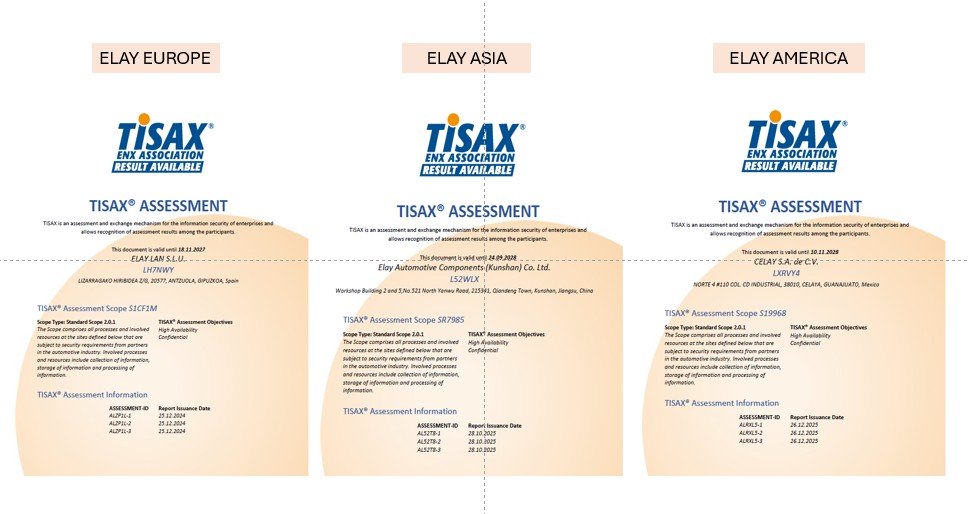

ELAY Group completes TISAX certification at all its plants

02/02/2026

ELAY Group has reached a strategic milestone in its commitment to information security standards in...

ELAY AMERICA celebrates 25 years of commitment, growth, and excellence

15/09/2025

This year, ELAY AMERICA, the Mexican plant of the Elay Group, proudly celebrates its 25th...

ELAY will be present at the 17th edition of Blechexpo 2025 in Stuttgart

22/09/2025

"From October 21 to 24, 2025, the Messe Stuttgart exhibition center will host the 17th edition of...